One of the benefits of Integrating a poka-yoke into the production process is that it can be used to:

Global outsourcing and shared suppliers serving an industry are drivers of which category of risk?

Which of the following benefits typically will be realized when switching from a functional to a cellular layout?

The primary consideration In maintenance, repair, and operating (MRO) supply systems typically is:

An effective approach to projecting requirements for materials with long lead times Includes which of the following options?

Moving average forecasting methods are best when demand shows:

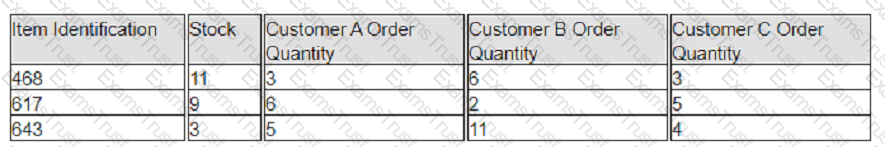

Exhibit:

A company has prioritized customers A, B, and C, filling orders in that sequence. What are the impacts to customer service levels for customers B and C?

In which of the following phases of the product life cycle is product price most effective in influencing demand?

Up-to-date Information about production order status is required to do which of the followingtasks?

The primary outcome of frequent replenishments in a distribution requirements planning (DRP) system is that:

When designing a production cell, which of the following items would be the most important consideration?

Risk pooling would work best for items with:

When starting an external benchmarking study, a firm must first:

The primary benefit that results from the cross-training of employees is:

The trade-off of increasing safety stock to improve customer fill rate would be a decrease in:

According to quality function deployment (QFD), customer needs are gathered through:

Which of the following trade-offs should be evaluated when determining where to place inventory in a multi-echelon supply chain network?

Check sheets can be used to:

A company decided not to pursue a business opportunity In a foreign market due to political Instability and currency fluctuations. Which risk control strategy did this business utilize?

Which of the following techniques would a group use to prioritize problems?

Which of the following statements characterizes a pull system In distribution management?

A manufacturer has a forecasted annual demand of 1,000,000 units for a new product. They have to choose 1 of 4 new pieces of equipment to produce this product. Assume that revenue will be $10 per unit for all 4 options.

Which machine will maximize their profit if the manufacturer anticipates market demand will be steady for 3 years and there is no residual value for any of the equipment choices?

MachineFixed CostVariable Cost per UnitAnnual Capacity

AS100.000$6 00800,000 units

B$200,000$5 501.000,000 units

C$250,000$5 001,200,000 units

D$1 000.000$4 501 400.000 units

One advantage of adopting a supply network perspective Is that it:

A newer automotive supplier has not fully developed its information technology (IT) systems. The supplier has Just received a contract from a large automotive manufacturer which requires the supplier to use electronic data interchange (EDI) transactions for receiving orders, sending advance ship notices (ASNs), and receiving invoice payments. What strategy can the supplier adopt to immediately meet the EDI requirements?

A company can easily change Its workforce, but inventory carrying costs are high. Which of the following strategies would be most appropriate during times of highly fluctuating demand?

A life cycle assessment (LCA) would be used to determine:

A logistics manager Is faced with delivering an order via rail or truck. Shipping via rail costs S300 and takes 14 days. Shipping via truck costs $600 and takes 3 days. If the holding cost is $40 per day, what is the cost to deliver the order?

A work center has 3 machines that are all run at the same time with a single worker. The work center has an efficiency of 75% and a utilization of 100%. What is the work center's capacity in standard hours for an 8-hour shift?

Which of the following measurements indicates there may be bias In the forecast model?

Typically, rough-cut capacity planning (RCCP) in a job shop environment would review which of the following work centers to determine the ability to execute the plan?

An example of an assignable cause of variation in process performance is:

A company's primary performance objective Is flexibility. Which of the following measurements is most important?

The production plan relates to a firm's financial planning because it is used to:

Which of the following items does the master scheduler have the authority to change in the master scheduling process?

Price negotiation is most appropriate when purchasing which of the following product categories?

Which of the following factors typically would distort a sales forecast that is based solely on shipment history?

A statistical safety stock calculation would be appropriate for:

Which of the following statements best characterizes enterprise resources planning (ERP) systems?

How would a master production schedule (MPS) be used In an assemble-to-order (ATO) manufacturing environment?

One of the most useful tools for analyzing the sustainable footprint is:

What activity is a useful element in the change process?

Which of the following methods places a replenishment order when the quantity on hand falls below a predetermined level?

Which of the following activities is an example of collaboration between suppliers and operations which would give more lead time visibility?

Which of the following tools is used to evaluate the impact that a production plan has on capacity?

In a rapidly changing business environment, a primary advantage of an effective customer relationship management (CRM) program is: