An organization purchases materials beyond current and anticipated requirements in expectation of a price increase or shortage, in the hope that it will profit from the sale of the materials at a later date. This describes which of the following buying strategies?

A company purchases raw materials from a domestic supplier that offers competitive overland transportation rates. The firm requires the goods be delivered to its manufacturing plant. Which of the following Incoterms® 2020 rules should be used if the firm wants risk to transfer at the manufacturing plant?

A supply manager is analyzing potential costs associated with the raw materials needed for a new product launch. Tooling costs are known, but the range of forecasts for future sales—and therefore demand for materials-varies widely. Given these circumstances, the supply manager should consider using which of the following?

A supply manager for a U.S. firm is tasked with negotiating domestic shipping terms. The terms must ensure that the supplier has liability for any damaged products and is responsible for filing any claims with the shipper. The terms must also allow the buying firm to pay the shipper directly for shipping costs. Which of the following will BEST accomplish this objective?

Which of the following modes of transportation BEST promotes international trade and offers a low cost option fortransporting large quantities of product?

XYZ, Inc. is a company based in the United States. XYZ purchases a large quantity of raw materials from a supplier in the Dominican Republic. The supplier packages the materials and delivers them to the shipping company designated by XYZ and loads them onto the ship. The contract specifies Free Carrier At (FCA) Caucedo, Dominican Republic. While the ship is still in port, a hurricane damages the ship and ruins its cargo. Under Incoterms® 2020 rules, who owns the shipment at this point?

A company determines that demand for an item is steady at 800 units per month, and that the cost of ordering and receiving the item is $300, regardless of how much is ordered. The per item charge is $5, and holding costs are 20% annually. Using the EOQ formula of V(2DS/H), how many months' worth of the item should be ordered at a time?

The supply manager for a semiconductor company receives an emergency phone call from the firm's factory manager, who states that the manufacturing equipment is down and that a replacement part is needed as soon as possible. The supply manager checks the stock for this part but finds nothing. In this situation, the supply manager should do which of the following?

A manufacturer is working to standardize high-volume, low-cost hardware components used in its assembly process. The manufacturer wants to transfer some of the risks associated with inventory carrying costs, warehousing costs, and re-stocking costs to the supplier. Which of the following will be MOST useful in accomplishing this goal?

A specialized sewing shop quilts fabrics for use in upholstered furniture. Various patterns are produced on different machines, each of which has its own set-up routine. At times, one type of machine is idle while others are backed up. The sewing floor supervisor finds new software which makes the machines' patterns interchangeable. Which of the following is the MOST likely result of upgrading to the new software?

A manufacturing firm redesigns its premier product to benefit from material standardization. This will entail re-tooling its manufacturing facility. The firm conducts a cost analysis using net present value (NPV) and considers four options. Option 1 is to make no change at all. Options 2, 3, and 4 represent different re-tooling configurations. The discount rate for NPV calculation is 10% per annum, and material costs are fixed for the next 3 years. The firm follows a three-year planning cycle and wishes to apply NPV over that time period to the calculations:

Option 1Option 2Option 3Option 4

Re-tooling Costs$0$500,000$800,000$950,000

Annual Material Costs$1,100,000$900,000$800,000$750,000

NPV = £ r.i (l*r/

What is the 3-year NPV of the best option’

A supply manager for JKL, Inc. is negotiating a contract with a supplier of a component. The component will be used in a new product JKL Is manufacturing and plans to bring to market early next year. Which of the following will be the MOST important provision for the supply manager to negotiate for?

A company is designing a new warehousing strategy. The firm wants to hire the most qualified personnel, utilize the best technology, and minimize the repetition of inventory across operations. Which of the following warehousing strategies will be BEST suited toward attaining the organization's goals?

Which of the following refers to an agreement between a buyer and supplier in which vendor-owned inventory is stored on the buyer's floor until it is used in production?

Which of the following is the MOST important reason for establishing and maintaining a supplier quality certification program?

An organization has a forecast for June of 125 units. However, 140 units actually sell. What is the exponential smoothing forecast for July if the alpha is 0.2?

A large retailer and one of its suppliers establish a process to combine intelligence from both organizations in order to improve product availability while reducing inventory, transportation, and logistics costs. This process is known as which of the following?

Which of the following requires investment recovery action’

A retailer of high-value consumer electronics experiences a significant increase in theft within its forward and reverse logistics operations, both of which are subcontracted to third parties. Which of the following is the FIRST course of action the retailer should undertake in order to mitigate loss within the subcontractors' chain of custody?

Which of the following is the GREATEST advantage of using component standardization in product design?

Which of the following is the PRIMARY benefit of project governance?

When executing a new project, which of the following is MOST important to a smooth transition?

A manufacturer must work to reduce cost of goods sold (COGS) to achieve profit objectives and remain competitive in a tight market. The manufacturer has long standing relationships with its main suppliers and a strong supply management department that conducts periodic reviews with the suppliers. Nevertheless, the manufacturer is not hitting targets. Which of the following is the BEST course of action for supply management to undertake in order to initiate improvements?

Which of the following refers to a computer-based system that determines the purchase requisition requirements that go into the manufacture of end items, and addresses an organization's operational, financial and marketing strategies?

A well-established retailer of consumer goods has earned a reputation for providing high quality merchandise at competitive prices. In recent years, however, the retailer has experienced a steady decline in sales within its stores. Which of the following is the BEST course of action for the retailer to take?

Which of the following is the BEST reason to use Monte Carlo simu-lations to improve a forecast7

A firm hires a contractor to build a new warehouse. During construction, the firm decides it wants to modify the contract to add an office area to the facility. Which of the following is the BEST course of action for the firm to take in this situation?

A company develops long range material forecasts, analyzes industry trends, determines commodities for value analysis, and assesses supplier capabilities to assure continual economic supply of goods and services. This company is engaged in

A vice president (VP) of supply management receives numerous complaints regarding the length of time it takes to receive products after they have been ordered. This has resulted in the company losing business due to late customer deliveries. Which of the following is the FIRST step the VP should take in order to address this issue?

XYZ, Inc. is implementing a new automated system in its distribution center. The supply manager is developing measures to evaluate the success of the automated system pilot. Which of the following is the BEST metric to measure overall success of the pilot7

A company finds that delays and cost overruns are creating problems in its service contracts. To improve this situation, which of the following should the firm do FIRST?

A wine bar which also serves tapas and sandwiches notices that its customer volume fluctuates significantly (depending on convention tourism and hotel night stays) and that wait times for seating are growing longer. As a result, managing demand for perishable food products is becoming more challenging.

Which of the following would be MOST useful in this scenario?

A supply manager is reviewing safety stock for a particular unit. The unit is small, Inexpensive, non-perishable, and easily stored, but is critical to the firm's manufacturing process. The following information is known about this unit:

Maximum lead time = 8 Days

Average lead time = 3 Days

Maximum daily usage = 6,000 Units

Average daily usage = 4,000 Units

What is the maximum safety stock that should be maintained for this unit?

Which of the following buying strategies refers to planning inbound material purchases and flows without the need for significant inventory levels7

Reducing the number of items that perform the same or similar function is known as

A firm completes its near level production, five-month demand plan for the next business planning cycle:

Month 1Month 2Month 3Month 4Month 5

Demand Forecast15,00020,00025,00025,00018,000

Production Plan (Regular Time)20,00020,00020,00020,00018,000

Production Plan (Overtime)5,000

Ending Inventory5,0005,000

Average Inventory2,5005,0002,500

Workforce PlanningStarting WorkforceMonth 1Month 2Month 3Month 4Month 5

Hires7

Layoffs2

Actual Workforce Size132020202018

Regular Time Hours Required2,0002,0002,0002,0001,800

Overtime Hours Required500

Costs

Regular time cost per unit$15

Overtime cost per unitS25

Monthly inventory cost per unit$1

Cost of hire$1,500

Cost of layoffS400

What is the cost of this demand plan?

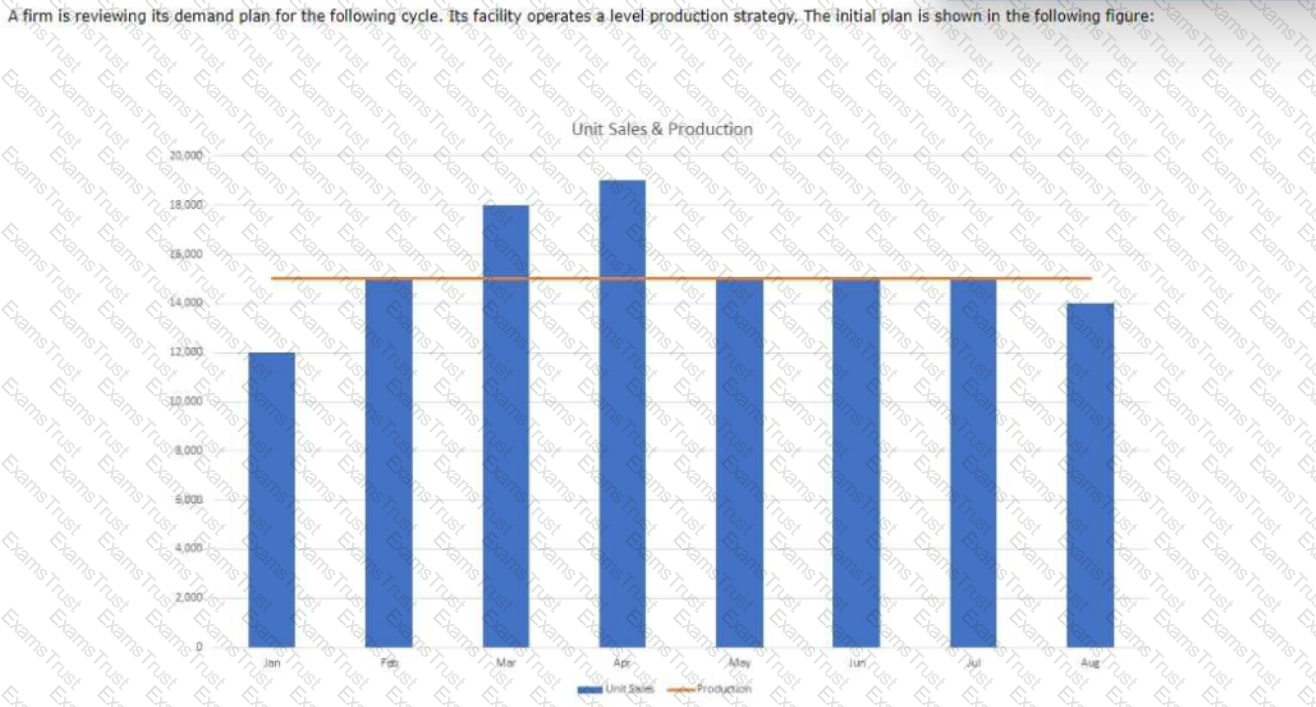

There are 10,000 units in stock for the beginning of January, and maximum inventory holding is 19,000 units. Sales are recorded at the end of the month.

Procurement receives a communication from one of its retailers that it is planning a promotional event in July. The retailer forecasts that it will require an additional 20,000 units. By how much should the level production strategy increase its monthly output of units in order to meet the requirements of the retailer and minimize overall inventory levels?

A supply manager negotiates a volume discount with a key supplier. The supplier will provide a discount on screws, bolts, and nuts, based on the quantity indicated on the purchase order (PO). Which of the following would be the BEST way for the buying firm to maximize the benefits of this discount?

Which of the following are the quickest ways to ship food products in order to ensure they do not spoil?

A project charter addresses which of the following areas?

Which of the following holds the supplier responsible for ensuring that stock is maintained at appropriate levels and replenished when needed at the purchaser s facility’

A scientific equipment company wants to encourage its key suppliers to participate in the firm's quality certification program. The process is detailed and time-consuming. Which of the following is likely to be the GREATEST benefit to the buying organization?

A firm that manufactures residential doors and windows runs short of rubber molding used in production. The next delivery from the contracted supplier is due in two working days. To maintain production, the firm's supply manager purchases 100 feet of material from a local supplier. This type of purchase is known as

A firm engaging in low-cost country sourcing wants to assume the least amount of risk when importing goods into its own country. Which of the following Incoterms® 2020 rules would be MOST useful in achieving this goal7

Which of the following refers to an operations management philosophy whose objective is to reduce waste and cycle time?

A chemical supply company creates a new liquid chemical product which must be shipped by tanker truck. The new chemical is expected to constitute 10% of the firm’s sales over the next five years. The company's other sales are all solid powder chemicals. Given these circumstances, which of the following will be the MOST cost effective method for the company to ship the new product’

MNO, Inc. operates within a volatile industry in which unforeseen demand and events often result in unreliable forecasts. Which of the following is the BEST way for MNO to generate better information about demand and improve forecast accuracy?

Which of the following is MOST likely to be an advantage of a standardization program?

A company logistics manager is informed that, because of an emergency, part of the firm's ocean-going cargo had to be thrown overboard. The losses are to be split 50/50 between the shipper and the freight company. Which of the following pertains MOST closely to this issue?

A firm is looking to expand to a larger warehouse. Which of the following should be given the GREATEST consideration when determining the new warehouse's environmental impact?